Plastic Barrier Film Heat Seal Testing for Packaging Quality Control

Plastic barrier film plays a decisive role in modern packaging systems, especially where protection against oxygen, moisture, and contamination is essential. However, strong barrier performance alone does not guarantee a successful package. The ability of a plastic barrier film to form stable, repeatable seals often determines whether a package survives filling, transportation, and storage. This is why plastic barrier film heat seal testing is a key activity for packaging development and quality control teams.

Heat seal testing provides a scientific way to evaluate how a plastic barrier film behaves under defined sealing conditions. By understanding this behavior early, manufacturers can reduce production risks, improve seal consistency, and shorten development cycles.

Heat Sealability and Heat Seal Testing for Plastic Barrier Film

Heat Sealability refers to the capacity of a plastic barrier film to create a functional seal when exposed to heat and pressure for a defined time. Because plastic barrier film structures often combine sealant layers with barrier and support layers, sealing behavior can vary significantly between materials.

Heat Seal Testing translates this behavior into measurable data. Among the available standards, ASTM F2029 establishes recognized laboratory practices for preparing heat seals and evaluating sealability trends of flexible barrier materials. Rather than duplicating production equipment, ASTM F2029 focuses on controlled and repeatable laboratory conditions, making it ideal for material comparison and process optimization.

Why Heat Seal Testing Matters for Plastic Barrier Film

In real packaging environments, seals may encounter stress before they fully cool or stabilize. Inadequate sealing can lead to leaks, contamination, or product loss. Heat seal testing helps prevent these failures by clarifying how sealing parameters influence seal formation.

Through systematic testing, packaging professionals can:

- Identify seal initiation temperatures

- Define stable sealing windows

- Compare different plastic barrier film constructions

- Detect sensitivity to process variation

These insights support both material selection and equipment setup.

Preparing Heat Seals in the Laboratory

ASTM F2029 specifies laboratory preparation of heat seals using hot-bar or impulse sealing techniques. During testing, operators produce seal specimens under carefully controlled temperature, pressure, and dwell time.

Each sealing condition represents a data point. By varying parameters in a structured way, laboratories can evaluate how plastic barrier film responds to incremental changes in heat input. This approach ensures that observed differences reflect material behavior rather than random process variation.

Evaluating Seal Strength After Heat Seal Testing

Once seals are prepared, their performance must be evaluated using appropriate mechanical tests, such as peel or tensile-based methods. These tests reveal how seal strength develops across different sealing temperatures.

A common outcome of plastic barrier film heat seal testing is the heat seal curve. This curve shows the relationship between sealing temperature and seal strength, allowing users to:

- Identify minimum acceptable sealing conditions

- Observe plateau regions where sealing becomes stable

- Detect transitions in failure modes

Such information is essential when setting process targets for production lines.

Supporting Reliable Testing with Professional Equipment

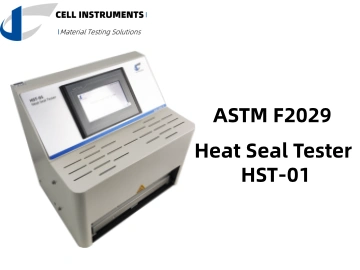

Consistent heat seal testing depends on precise control of temperature, pressure, and dwell time. The Cell Instruments HST-01 Heat Seal Tester supports plastic barrier film evaluation by providing stable sealing conditions aligned with ASTM F2029 practices.

In laboratory environments, the HST-01 enables reproducible seal preparation, helping quality and R&D teams generate dependable heat seal curves and comparative data without overcomplicating test workflows.

Applications Across Packaging Industries

Plastic barrier film heat seal testing applies broadly across packaging sectors, including:

Food and beverage packaging

Pharmaceutical and medical packaging

Chemical and industrial flexible packaging

In each case, seal reliability directly affects safety, compliance, and brand reputation.

Conclusion

Plastic barrier film performance depends not only on barrier properties but also on predictable sealing behavior. By applying heat seal testing based on ASTM F2029, packaging professionals gain critical insight into heat sealability and process sensitivity.

With structured testing methods and reliable instruments such as the Cell Instruments HST-02 Heat Seal Tester, organizations can improve seal integrity, reduce production risk, and deliver consistent packaging quality with confidence.